3800-CNC-PUR Industrial Edge Banding

3800-CNC-PUR Industrial Edge Banding

Best Quality, Single Price

Innovative, modern, and ergonomic in design, the 3800 CNC-PUR Industrial Automatic Edge Banding Machine, with its fast, compact, and user-friendly system and design patented by HAKİ SABIR, features CNC control and a color touch screen. It is designed to set a new standard of the highest quality for factories and subcontractors, handling PVC, foil, melamine, and ABS applications from 0.4 mm to 3 mm in thickness.

Machine Features

Patented Systems of HAKİ SABIR Used for Years

Patented Magic Trim System: Processes three surfaces with a single blade, avoiding the dips found in multi-blade systems.

Height Adjustment and Centering: Managed with an automatic lifting system.

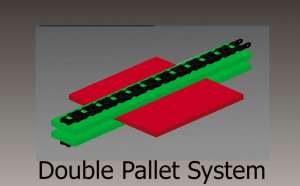

Rubber-Coated Dual Pallet System: For gripping narrow and large pieces.

Front (Jumping) Milling Unit.

CNC-Controlled Color Screen and Touch Adjustment Application.

Remembers 100 Different Jobs and Makes Automatic Adjustments.

Front Milling & Trim Spindle Motor Connections: Not foot-operated; adjustments remain stable without heating issues.

Automatic Pricing, Quantity Counting & Measurement.

Automatic Transition Between Desired PVC Sizes.

PUR Glue Unit (polyurethane reactive) also compatible with hot-melt glue.

Hot Air Laser Band System (optional).

Step PVC Drive.

Patented Side Pressure System: No pressure applied to front and rear excesses.

Quick and Easy Adjustment and Setup.

Patented Manufacturing System: Stabilized hard monoblock structure and high product quality.

Patented Milling Systems: Minimized vibration for smooth operation.

Wide Pallet, Self-Passing Chain.

Problem-Free Equipment, Machine Safety Systems, Two-Year Warranty.

Control Systems

All operational units, including head and end trimming, corner rounding, automatic transition between thin and thick PVC, normal soft MDF, quantity counting, measurement, and pricing, are controlled via a CNC color touch screen. It remembers 99 different jobs and makes automatic adjustments. High-frequency motors are controlled by inverters and include an emergency switch. Electronic systems are enclosed and gasketed to protect them from dust and other environmental factors.

Main Chassis

The patented HAKİ SABIR manufacturing and rubber-coated dual pallet system grips both narrow and large pieces. It is the shortest machine in its class, made from precision-measured monoblock steel to ensure maximum flatness, accurate adjustment, and full contact with the floor.

Front Siper

CNC automatically adjustable from the touch color screen.

Feeder

Designed to load edge bands from large-diameter carrier coils.

Feeding and Upper Pressure

Enhanced quality rubber-coated dual pallet system consists of polyemit and rubber pallets connected to articulated chains over precisely machined steel bearings. Height adjustment and centering are done with an automatic lifting system.

Front Milling Unit (Jumping)

The patented HAKİ SABIR system uses two top blades with automatic adjustable tracking to process defective materials like particle board, MDF, and chipboard with skipping, simultaneous, and separate working features. (Optional Dia blade)

Glue Application

The PUR Glue Unit (polyurethane reactive) resists water, moisture, and high temperatures and can also use hot-melt glue.

The Hot Air Laser Band System (optional) does not use glue. Panels look like single panels with painted edges on all four sides with no glue marks. Results are of excellent quality and surpass all aesthetic standards. Zero glue marks are achieved with a special polypropylene (PP 0.2mm thickness) layer on edge bands made of PVC, acrylic PP, ABS, etc. This layer melts using a compressed hot air system (400-500 °C), with a maximum working speed of 15 m/min on 18 mm material. The Moxsabır hot air laser band system is simple, requires no maintenance or cleaning, and is more resistant to water, moisture, and chipping compared to EVA glue systems. It can be mounted on any model or brand machine with minor modifications and is the most economical option. Haki Sabir’s patented Moxsabır edge banding machines are capable of using any type of glue (EVA or PUR).

Pulling & Cutting

The patented mechanical Step PVC Drive system by HAKİ SABIR can cut edge banding materials up to 3 mm thickness and 50 mm height. No adjustment is needed when transitioning from thin to thick materials.

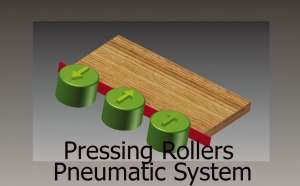

Press Rollers

The patented HAKİ SABIR system consists of three rollers with approach sensors and a CNC-controlled pneumatic system. The initial pressure grip is driven and automatically adjusts the pressure; it is the only machine that does not apply pressure to the excess material at the front and back of the workpiece.

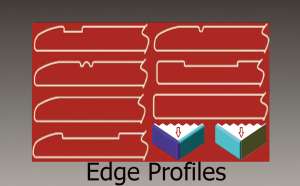

Top Processing Head & End Corner Rounding (MAGIC)

The patented HAKİ SABIR system, with CNC automatic adjustment from the touch color screen, is easy to use and processes three surfaces with a single blade in one direction. It is a head, end, and top processing system that does not damage the workpiece. The blade diameter is 42 mm. It automatically adjusts transitions from 0.40 mm to 3 mm thickness for sharp corners, soft, post, and flat pieces. It eliminates adjustment issues caused by heating with a connection system and a dust and chip vacuuming system, operating with an external cooling 300 Hz motor at 18,000 rpm.

Bottom Processing Head & End Corner Rounding (MAGIC) Head, End, Flat & Radius Cutting

The patented HAKİ SABIR system, with CNC automatic adjustment from the touch color screen, is easy to use and processes three surfaces with a single blade in one direction. It is a head, end, and bottom processing system that does not damage the workpiece. The blade diameter is 42 mm. It automatically adjusts transitions from 0.40 mm to 3 mm thickness for sharp corners, soft, post, and flat pieces. It eliminates adjustment issues caused by heating with a connection system and a dust and chip vacuuming system, operating with an external cooling 300 Hz motor at 18,000 rpm.

Scraping Group

The patented HAKİ SABIR system is a CNC automatic Z-Y directional adjustable scraping unit with independent upper and lower radii. It can automatically adjust thicknesses from 0.40 mm to 3 mm.

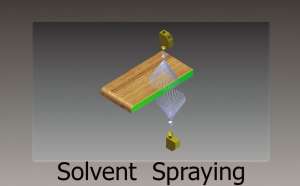

Solvent Spraying

Sprays the liquid used for glue cleaning and band surface polishing.

Polishing Group

Polishes and finishes the band surface using solvent with two independent 1500 rpm motors.

Channel Opening

Angled jumping entry and exit distances are CNC automatically adjustable from the touch color screen.

Safety Systems

The machine’s electro-pneumatic components automatically lubricate and clean the system during operation. If phases or air are not available, the machine protects itself and prevents damage to its systems. The machine monitors the feeding interval and reports faults on the touch PLC color screen.

| Power Supply Voltage | Electrical Level | 380-220 / 50 hz-380-220 В / 50 Гц |

| Nominal Current | Nominal Current | 38 A-38 A |

| Band Thickness | Edge Material Thickness | 0,4-3 mm-0,4-3 мм |

| Workpiece Thickness | Board Thickness | 10-50 mm-10-50 мм |

| Working Speed | Speed | 15- m/dk-15- м/мин |

| Total Electrical | Total Electrical Power | 14.4 Kw-14.4 кВт/ч |

| Total Air | Total Air Pressure | 6 Bar-6 Бар |

| Air Consumption | Total Air Usage | 200 lt/dk-lt/min-200 л/мин |

| Front Milling | Front Milling | 2 X 1.5 kw/ 12000 Rpm-2 X 1.5 кВт/ 12000 об/мин- |

| Trim Milling | Trimming | 2 X 0,75 kw / 18000 Rpm-4 X 0,75 кВт/ 18000 об/мин |

| Lift Motor | 1 x 0.25 kw | |

| Polishing Motor | Buffing Motor | 0.16 kw / 150 Rpm-0.16 кВт / 150 об/мин |

| Laser Heater | 3 kw | |

| Adhesive Heater | 1.5 kw | |

| Adhesive Pot Motor | Glue Boiler Engine | 0.16 kw / 150 Rpm-0.16 кВт / 150 об/мин |

| PVC Stepper Motor | Pvc Step Engine | 9 x 0.13 kw-9 x 0.13 кВт |

| Double Pallet Motors | Double pallet system | 2 X 2.2 kw / 1500 Rpm-servo 2 X 2.2 кВт / 1404 об/мин |

| Machine Length | Machine Length | 3800 mm-3800 мм |

| Machine Width | Machine Width | 800 mm-800 мм |

| Machine Height | Machine Height | 1500 mm-1500 мм |

| Machine Weight | Machine Weight | 1100 kg-1100 кг |