4600-W-CNC-PUR Industrial Edge Banding

4600-W-CNC-PUR Industrial Edge Banding

Top Quality at a Single Price Innovative, modern, and ergonomic in structure, the fastest in its class, with the shortest and easiest usability, HAKI SABIR’s patented PLC-controlled, color touchscreen 4600-W-NC-PUR Industrial Edge Banding Machine; designed for factories and subcontractors with a new standard of the highest quality for applications ranging from 0.4 mm to 8 mm thickness in Solid Wood, PVC, foil, melamine, and ABS coating.

Machine Features

Patented Systems Used for Years by HAKİ SABIR

Patented Magic Trim System Processes Three Surfaces with a Single Blade, Eliminating Dips Seen in Multi-Blade Systems

Height adjustment and centering are done with an automatic lifting system.

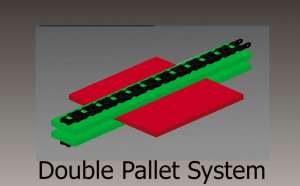

Rubber-coated dual pallet system for gripping narrow and large pieces.

Front (Jumping) milling unit.

CNC controlled color screen and touchscreen adjustment application.

Front milling & trim spindle motor connections are not on the floor, preventing adjustments from being disturbed due to overheating.

Stores 100 different jobs in memory and makes automatic adjustments.

Automatic pricing, quantity counting & meter measurement.

Automatic transition between thin and thick PVC.

PUR (Polyurethane Reactive) Glue Unit can also use hot melt glue.

Hot air laser band system (optional).

Step PVC driver.

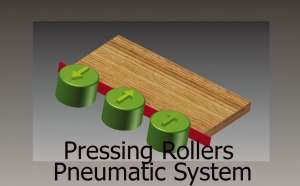

Patented pressure application system that does not apply pressure to front and rear excesses.

Fast, easy setup and assembly capability.

Patented manufacturing system, stabilized rigid monoblock structure, and high product quality.

Patented milling systems, enabling vibration-free operation.

Wide pallet, self-passing chain.

Trouble-free hardware, machine safety systems, two-year warranty.

CONTROL SYSTEMS: Controls all working units such as start-end cutting, corner rounding, automatic transition to desired PVC size, normal soft MDF, piece counter, meter counter, and pricing through a CNC color touchscreen with the ability to store 99 different jobs in memory and perform automatic adjustments. High-frequency motors are controlled by converters and include an emergency stop switch. Electronic systems are sealed and gasketed to prevent effects from dust, etc.

MAIN FRAME: Patented manufacturing by HAKI SABIR with a rubber-coated dual-pallet system that grips small and large pieces. It’s the shortest machine in its class made from monoblock steel, ensuring maximum smoothness, precise adjustment, and full contact with the ground.

FEEDER: Designed to load edge bands from large diameter carrier coils.

FEEDING AND PRESSING: Consists of polyemit and rubber pallets connected to articulated chains on precision-machined steel beds coated with rubber, offering improved quality. Height adjustment and centering are done with an automatic lifting system.

PRE-MILLING UNIT (JUMPING): Patented system by HAKI SABIR with two top blades, allowing jumping, simultaneous, and separate operation to ensure smooth processing of materials like mis-cut chipboard, MDF, plywood, etc. (optional Dia blade)

GLUE APPLICATION: Uses PUR (polyurethane reactive) glue unit, resistant to water, moisture, and high temperatures. Can also use Hot-Melt glue. The hot air laser tape system (optional) achieves edge bonding without using glue, resulting in perfect quality with no glue marks on all aesthetic standards. Specialized for PVC, Acrylic PP, ABS, etc., edge bands.

TRIMMING & CUTTING: Mechanical-step PVC drive trimming and cutting system patented by HAKI SABIR can cut edge banding materials up to 10 mm thickness and 60 mm height without requiring adjustments when transitioning from thin to thick materials.

PRESSURE ROLLERS: Consists of 3 rollers controlled by PLC with proximity sensors, automatically adjusting pressure without applying pressure to excess material in front and behind the material to be bonded.

START-END CUTTING SAW UNIT: Mechanical tracking system for cutting wood adhered to the material according to its measurements.

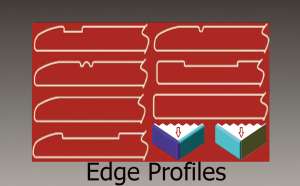

TOP PROCESSING START & END CORNER ROUNDING (MAGIC): Patented system by HAKI SABIR, easy to use with a single blade and direction, processes three surfaces of the part without damaging it on a steel chassis. Automatically adjusts transitions from 0.40 mm to 2 mm for square, post, and flat parts. Uses a 300 Hz motor operating at 18,000 rpm, externally cooled, eliminating adjustment problems due to heat.

BOTTOM PROCESSING START & END CORNER ROUNDING (MAGIC) START END STRAIGHT & RADIUS CUTTING: Patented system by HAKI SABIR, easy to use with a single blade and direction, processes three surfaces of the part without damaging it on a steel chassis. Automatically adjusts transitions from 0.40 mm to 2 mm thickness for square, post, and flat parts. Uses a 300 Hz motor operating at 18,000 rpm, externally cooled, eliminating adjustment problems due to heat.

SCRAPING GROUP: Independently adjustable scraping unit with bottom and top radius adjustments in z-y directions from HAKI SABIR. Automatic adjustment can be made from 0.40 mm to 2 mm thickness.

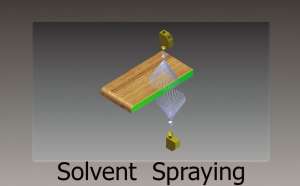

SOLVENT SPRAY: Sprays liquid used for glue cleaning and surface polishing.

POLISHING GROUP: Uses two independent 1500 rpm motors for polishing and finishing the edge surface with solvent.

CHANNEL OPENING: Adjusts jumping entry and exit distances through a PLC color touchscreen (optional).

SAFETY SYSTEMS: The machine’s electro-pneumatic components automatically lubricate and clean during operation. It protects itself from damage if phases or air are not received and reports faults on the touch NC color screen.

| Mains Voltage | Electrical Level | 380-220 / 50 hz-380-220 В / 50 Гц |

| Nominal Current | Nominal Current | 60 A-60 A |

| Band Thickness Melamine Plastic (PVC, PP, ABS) | Edge Material Thickness | 0,4-3 mm-0,4-3 мм |

| Workpiece Thickness | Board Thickness | 10-50 mm-10-50 мм |

| Operating Speed | Speed | 15- m/dk-15- м/мин |

| Total Electricity | Total Electrical Power | 22.8 Kw-22.8 кВт/ч |

| Total Air | Total Air Pressure | 6 Bar-6 Бар |

| Air Consumption | Total Air Usage | 200 lt/dk-lt/min-200 л/мин |

| Pre-milling | Front Milling | 2 X 1.5 kw/ 12000 Rpm-2 X 1.5 кВт/ 12000 об/мин- |

| Trimming cutter | Trimming | 6 X 0,75 kw / 18000 Rpm-6 X 0,75 кВт/ 18000 об/мин |

| Lift Motor | 1 x 0.25 kw | |

| Polishing Motor | Buffing Motor | 2 X 0,18 kw / 1310 Rpm-2 X 0,18 кВт / 1310 об/мин |

| Laser Resistance | 3 kw | |

| Adhesive Resistance | 1.5 kw | |

| Adhesive Tank Motor | Glue Boiler Engine | 0.16 kw / 150 Rpm-0.16 кВт / 150 об/мин |

| PVC Step Motor | Pvc Step Engine | 9 x 0.13 kw-9 x 0.13 кВт |

| Minifix Servo Motor | 1 x 2.2 kw | |

| Dual Pallet Motors | Double pallet system | 2 X 2.2 kw / 1500 Rpm-servo 2 X 2.2 кВт / 1404 об/мин |

| Machine Length | Machine Length | 4800 mm-4800 мм |

| Machine Width | Machine Width | 800 mm-800 мм |

| Machine Height | Machine Height | 1500 mm-1500 мм |

| Machine Weight | Machine Weight | 1100 kg-1100 кг |