2600-TS Automatic Edge Banding

2600-TS Automatic Edge Banding

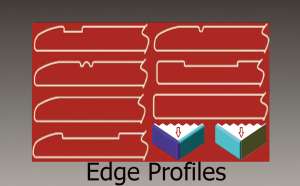

Easy to use, single-blade, unidirectional processing system for handling three surfaces of a part. Mounted on a steel chassis, it does not damage the part. The blade diameter is 42 mm. It automatically adjusts for transitions from 0.40 mm to 2 mm thickness for straight, post, and soft corner parts. The system eliminates adjustment issues caused by heating with its connection, and features a vacuum system for dust and shavings. It is powered by external cooling 300 Hz motors running at 18,000 RPM.

Machine Features

- Patented Systems Used for Years in HAKİ SABIR

- Patented Magic Trim System: Processes three surfaces with a single blade, avoiding the gouges found in multi-blade systems.

- Uses hot-melt adhesive.

- Step motor for PVC drive and measurement.

- Trim spindle motor connections are not from the foot, so adjustments are not affected by heating.

- Quick and easy adjustment and setup.

- Patented manufacturing system with a stabilized, solid monoblock structure and high product quality.

- Patented milling systems with minimized vibration for smooth operation.

- Wide pallet with self-locking chain.

- Problem-free equipment, machine safety systems, two-year warranty, and complies with CE standards.

CONTROL SYSTEMS:

- End cutting, corner rounding, automatic transition between thin and thick PVC, and all operating unit controls are managed manually. High-frequency motors are controlled by inverters and include an emergency switch. The electronic systems are enclosed with covers and seals to protect them from dust and other environmental factors.

MAIN FRAME:

- The shortest machine in its class, made from precision-measured monoblock steel with a patented manufacturing system by HAKİ SABIR, ensures maximum smoothness, accurate adjustment, and full contact with the ground.

FEEDER:

- Designed for loading edge banding materials from large-diameter carrier coils.

FEED AND TOP PRESSURE:

- Composed of polyamide and rubber pallets connected to articulated chains on high-quality, precisely machined steel bearings. Height adjustment and centering are done with an automatic lifting system.

ADHESIVE APPLICATION:

- Capable of using hot-melt adhesive.

PULLING & CUTTING:

- HAKİ SABIR’s patented mechanical-step PVC drive pulling and cutting system can cut edge banding materials up to 10 mm thick and 50 mm high. Adjustment is not required when transitioning from thin to thick materials.

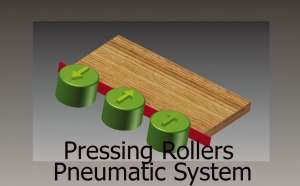

PRESSURE ROLLERS:

- Consists of a system with two rollers.

TOP PROCESSING HEAD & END CORNER ROUNDING (MAGIC):

- HAKİ SABIR’s patented, user-friendly system with a single blade and one-way movement processes three surfaces of the piece without damaging it on the steel chassis. The blade diameter is 42 mm. Automatic adjustment is made for transitions from 0.40 mm to 2 mm thicknesses of sharp corners, soft, post, and flat pieces. It eliminates adjustment issues due to heating with its connection, dust, and shavings vacuuming system, and operates with a 300 Hz motor running at 18,000 rpm.

BOTTOM PROCESSING HEAD & END CORNER ROUNDING (MAGIC) END STRAIGHT & RADIUS CUTTING:

- HAKİ SABIR’s patented, user-friendly system with a single blade and one-way movement processes three surfaces of the piece without damaging it on the steel chassis. The blade diameter is 42 mm. Automatic adjustment is made for transitions from 0.40 mm to 2 mm thicknesses of sharp corners, soft, post, and flat pieces. It eliminates adjustment issues due to heating with its connection, dust, and shavings vacuuming system, and operates with a 300 Hz motor running at 18,000 rpm.

SCRAPING UNIT:

- (OPTIONAL) HAKİ SABIR’s patented independent top and bottom radius scraping unit.

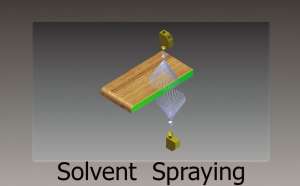

SOLVENT SPRAYING:

- Sprays the liquid used for adhesive cleaning and polishing the band surface.

POLISHING UNIT:

- Polishes and buffs the band surface with solvent assistance using two independent motors running at 1,500 rpm.

SAFETY SYSTEMS:

The machine’s electro-pneumatic components automatically perform system lubrication and cleaning during operation. If power phases or air supply are missing, the machine protects itself and prevents damage to its systems. It also controls the feeding gap for the workpiece.

| Şebeke Gerilimi | Electrical Level | 380-220 / 50 hz-380-220 В / 50 Гц |

| Nominal Akım | Nominal Current | 14 A-14 A |

| Bant Kalınlığı | Edge Material Thickness | 0,4-3 mm-0,4-3 мм |

| İş Parcası Kalınlığı | Board Thickness | 10-50 mm-10-50 мм |

| Çalışma Hızı | Speed | 10- m/dk-10- м/мин |

| Toplam Elektrik | Total Electrical Power | 5.25 Kw-5.25 кВт/ч |

| Toplam Hava | Total Air Pressure | 6 Bar-6 Бар |

| Hava Tüketimi | Total Air Usage | 180 lt/dk-lt/min-180 л/мин |

| Trim Freze | Trimming | 2 X 0,75 kw / 18000 Rpm-2 X 0,75 кВт/ 18000 об/мин |

| Polisaj Motoru | Buffing Motor | 2 X 0,18 kw / 1310 Rpm-2 X 0,18 кВт / 1310 об/мин |

| Tutkal Rezistans | 1.5 kw | |

| Tutkal Kazan Motoru | Glue Boiler Engine | 0.25 kw / 150 Rpm-0.25 кВт / 150 об/мин |

| Pvc Step Motor | Pvc Step Engine | 1 x 0.13 kw-1 x 0.13 кВт |

| Palet Motoru | Pallet Engine | 1 X 1.1 kw / 1500 Rpm- 1 X 1.1 кВт / 1404 об/мин |

| Makinenin Uzunluğu | Machine Length | 2600 mm-2600 мм |

| Makinenin Genişliği | Machine Width | 800 mm-800 мм |

| Makinenin Yüksekliği | Machine Height | 1500 mm-1500 мм |

| Makinenin Ağırlığı | Machine Weight | 640 kg-640 кг |