3100-PTS Automatic Edge Banding

3100-PTS Automatic Edge Banding

With the best quality and a single price, the 3100-PTS Automatic Edge Banding Machine is innovative, modern, and ergonomically designed. It is the most energy-efficient in its class, offering the shortest and easiest usage. Its system and design are patented by HAKİ SABIR. Designed for workshops, factories, and subcontractors, it sets a new standard of high quality, accommodating PVC, foil, laminate, and ABS applications from 0.4 mm to 3 mm thickness.

Machine Features

- Patented Systems for HAKİ SABIR Used for Years

- Patented Magic Trim System Works on Three Surfaces with a Single Blade No Dives as in Multi-Blade Systems

- Uses Hot – Melt glue

- Stepper Motor PVC Driver-Measuring Measurement

- Front (Jumping) Milling Unit.

- Front Milling & Trim Spindle Motor Connections Are Not From The Stand, Their Settings Will Not Be Deteriorated Due To Heating

- Quick, Easy Adjustment and Installation Possibility.

- Patented Manufacturing System, Stabilized Rigid Monoblock Structure and High Product Quality.

- Patented Milling Systems, Minimized Vibration-Free Working Opportunity

- Wide Track, Rapture Chain.

- Problem-free Hardware, Machine Safety Systems, Two Year Warranty. Compliant with CE Norm

CONTROL SYSTEMS:

Head-end cutting, corner rounding, thin-thick PVC automatic switching, and controls of all working units are done manually. High frequency motors are controlled by inverters and include an emergency switch. Electronic systems are covered and sealed to prevent them from being affected by dust etc.

MAIN CHASSIS:

It is the shortest machine in its class, manufactured from monoblock steel and precisely measured to ensure maximum smoothness, correct adjustment and full contact with the ground, with HAKİ SABIR’s patented manufacturing system.

FEEDER:

It is designed to load edgebands from large diameter carrier coils.

FEEDING AND OVERPRINTING:

It consists of polyamide and rubber pallets connected to jointed chains on quality, precision-processed steel beds. Height adjustment and centering; It is done with an automatic lifting system.

FRONT MILLING UNIT (WITH JUMPING):

HAKİ SABIR’s patented system, with two ball knives with tracking system, allows smooth processing of materials such as incorrectly cut chipboard, mdf, chipboard, etc. with its skipping, working together and separately feature. (optional Dia knife)

APPLYING GLUE:

Can use Hot – Melt glue

DRAWING & CUTTING:

The mechanical – Step PVC Drive pulling and cutting system, patented by HAKİ SABIR, is capable of cutting edge banding materials up to 10 mm thick and 50 mm high. Metering Measurement: It does not require adjustment when changing from thin to thick material.

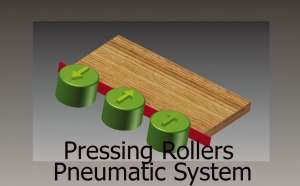

PRINTING ROLLERS:

It is a system consisting of 2 rolls.

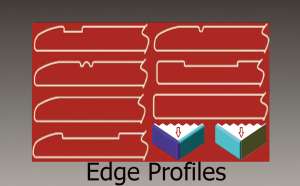

TOP MACHINING STARTING & END CORNER ROUNDING (MAGIC):

It is a head, end and top processing system patented to HAKİ SABIR, easy to use, moving in one direction with a single blade, capable of processing three surfaces of the part, and does not damage the part on a steel chassis. Blade diameter is 42 mm. It automatically adjusts the transitions of vertical corner soft, post and flat parts from 0.40 mm to 2 mm. Its connection eliminates the problem of adjustment distortion due to heating; The system that vacuums dust and sawdust is externally cooled 300 Hz motors running at 18000 rpm.

SUB MACHINING HEAD & END CORNER ROUNDING (MAGIC) HEAD END STRAIGHT & RADIUS CUTTING:

It is a head, end and bottom processing system patented to HAKİ SABIR, easy to use, moving in one direction with a single blade, capable of processing three surfaces of the part, and does not damage the part on a steel chassis. Blade diameter is 42 mm. It automatically adjusts the transitions of vertical corner soft, post and flat parts from 0.40 mm to 2 mm thick. Its connection eliminates the problem of adjustment distortion due to heating; The system that vacuums dust and sawdust is externally cooled 300 Hz motors running at 18000 rpm.

SCRAPPING GROUP:

(OPTIONAL) HAKİ is a scraping unit with upper and lower radii, independent of each other, patented by SABIR.

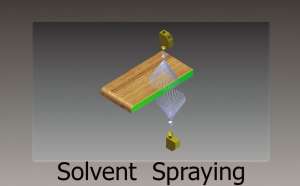

SOLVENT SPRAYING:

It sprays the liquid used in glue cleaning and polishing the tape surface.

POLISHING GROUP:

It polishes and polishes the belt surface with the help of solvent with two independent 1500 rpm motors.

SAFETY SYSTEMS:

The electro-pneumatic parts of the machine perform automatic lubrication cleaning of the systems during operation; If the phases and air do not come, the machine protects itself and does not cause any damage to its systems. The part controls the feed range. Compliant with CE Norm.

| Mains Voltage | Electrical Level | 380-220 / 50 hz-380-220 В / 50 Гц |

| Nominal Current | Nominal Current | 22 A-22 A |

| Band Thickness | Edge Material Thickness | 0,4-3 mm-0,4-3 мм |

| Workpiece Thickness | Board Thickness | 10-50 mm-10-50 мм |

| Working Speed | Speed | 10- m/dk-10- м/мин |

| Total Electrical | Total Electrical Power | 8.25 Kw-8.25 кВт/ч |

| Total Air | Total Air Pressure | 6 Bar-6 Бар |

| Air Consumption | Total Air Usage | 200 lt/dk-lt/min-200 л/мин |

| Front Milling | Front Milling | 2 X 1.5 kw/ 12000 Rpm-2 X 1.5 кВт/ 12000 об/мин- |

| Trim Milling | Trimming | 2 X 0,75 kw / 18000 Rpm-4 X 0,75 кВт/ 18000 об/мин |

| Polishing Motor | Buffing Motor | 2 X 0,18 kw / 1310 Rpm-2 X 0,18 кВт / 1310 об/мин |

| Adhesive Pot Motor | 1.5 kw | |

| Adhesive Pot Motor | Glue Boiler Engine | 0.25 kw / 150 Rpm-0.25 кВт / 150 об/мин |

| PVC Stepper Motor | Pvc Step Engine | 1 x 0.13 kw-1 x 0.13 кВт |

| Pallet Motor | Pallet Engine | 1 X 1.1 kw / 1500 Rpm- 1 X 1.1 кВт / 1404 об/мин |

| Machine Length | Machine Length | 3100 mm-3100 мм |

| Machine Width | Machine Width | 800 mm-800 мм |

| Machine Height | Machine Height | 1500 mm-1500 мм |

| Machine Weight | Machine Weight | 800 kg-800 кг |